Together we Trotect the world against food losses

Your zero food waste partner

Food losses and production failures are inevitable during the food production process. However, these products are too valuable to end up as waste. Trotec transforms plant-based former foodstuffs from industrial food companies (bakeries, producers of breakfast cereals, sweets, chocolate, etc.) and the retail sector (packaged goods) into a circular ingredient for animal feed.

Collaborating with Trotec therefore means reducing food waste, contributing to a circular economy and a sustainable future.

Full partnership

Trotec not only valorises your products in the most sustainable and economical way, we also offer a full partnership:

- via prevention. Using artificial intelligence (AI), Trotec has developed systems that can detect the production lines which generate the most losses. This allows these sensitive points to be analysed, treated and optimised by food producers

- via its own proactive, punctual and reliable logistics organisation (planning, drivers, trucks, containers, bioboxes, walking floors, etc.)

- via tailor-made filling and tilting systems that can be seamlessly integrated into your production process (integration, automation, digitalisation)

- via an accessible and deployable technical maintenance team

- via our unique guidance/consulting on legislation, food safety and quality

Thanks to our total approach, we will not only efficiently relieve you of your food losses and production failures, but we can also help reduce them!

Why work with Trotec?

Trotec stands for worry-free service, full partnership, 24h/7d and above all future-oriented!

Processing by-products creates a lot of added value for food companies. Trotec’s innovative production technologies ensure that the secondary flows remain in the food chain.

So, working with Trotec contributes to a strong circular economy. At the same time, you help reduce the ecological footprint and ensure that appropriate verifiable sustainability, CO2 emissions and food recovery targets can be set. As a food company, this is information you would want to tell the world about in your sustainability and annual reports.

Installation of filling and tilting system with smart sensors

Trotec offers customer-focused automated filling and tilting systems to load the by-products into containers in an easy and ergonomic way.

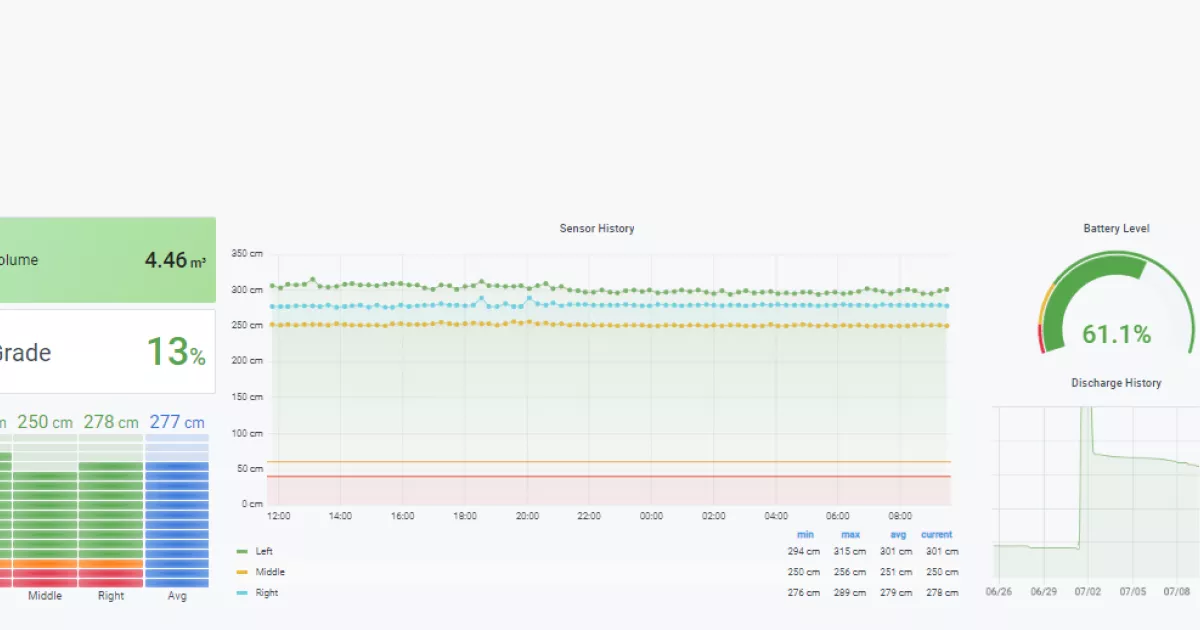

AI aided IoT systems

These filling systems run on innovative software that registers the weight and/or volume of food losses per line, per department and per shift. Online reports give the producer insights into the generated production failures. This IoT application enables the transport department to optimize the logistic process.

Bioboxes

Bioboxes are used for smaller volumes.

These hard-wearing containers can be reused after a thorough clean in an automated washing system. The use of bioboxes help to reduce the share of disposable or lost packing material.

Punctual and reliable logistic support

The process starts with the collection of secondary streams at the food company with our own transport solution. Collections are mainly done with containers specially designed for food products.

A story we can unpack with

With a state-of-the-art unpacking system packing material is efficiently separated from the basic raw materials.

We always look for the most sustainable solution with regard to the separated packaging. Nothing goes to waste.

We valorize the following products into a high-quality circular ingredient for animal feed.

Trotec processes both packaged and unpackaged former foodstuffs originating from the food industry and retail. To ensure microbiological stability, these products receive thermal treatment at Trotec. The focus is therefore primarily on food products whose dry matter content is at least 40%.

Bread, biscuits and dough

All ingredients and products from (industrial) bakeries

Chips & snacks

Surpluses from potato processing companies

Chocolate

Chocolate producers

Grain products

Breakfast cereals, mueslis

Sweets

Recuperation of various sweets

Packed products

Surpluses from the retail sector